Procurement and purchasing - Steps, process and key differences

What they mean in a business context

Literally speaking, the terms purchasing and procurement both appear to stand for a similar meaning. However, in a business context, they are far from being so. While they do have their similarities one focuses on transactional functions, for example, while the other is concerned with the strategic process of sourcing products.

The confusion when in the procurement vs purchasing debate is not uncommon. In fact, for smaller organizations, this distinction does not really count for much. However, as your business grows, not knowing the difference between the two can have negative effects on your business.

Here, we take a more detailed look at this distinction. We will attempt to give concrete definitions of the two, find out what the steps and processes involved are and then highlight the key differences. We will also take a look at how you can improve your company’s procurement process as well as a few other relevant questions on the topic.

What is purchasing in business?

Whenever your business or organization is acquiring goods or services to accomplish its goals the process followed is called purchasing. Paying employees’ salaries, renting new office space, or even buying a new microwave for the office pantry are all, if done with company money, considered to be purchasing.

The definition of purchasing emphasizes the fact that purchasing, as a process, is a subset of procurement. While procurement is a much more elaborate series of actions, purchasing starts and ends with placing and receiving an order.

To streamline this process, many businesses now rely on purchasing cards that allow teams to make controlled, trackable purchases with ease.

5-step purchasing process

While purchasing processes may vary across companies and industries a general framework can be formulated using these five steps:

1. Receiving the purchase requisition (PR)

The first step to placing an order for goods and services required by various or a particular business unit typically involves raising a Purchase Request (PR). The PR should ideally contain any required information regarding the deliverables expected from the vendor.

After the PR is raised it should then go through an approval workflow and once all approvals are obtained what is issued is called a Purchase Order (PO). The PO is sent to the vendor stating all particulars of the order required.

Purchase order management is also an integral part of ensuring that all order-related information is consistent in both the PO and the invoice the vendor will later raise.

2. Obtaining and evaluating vendor quotes

The next step should involve choosing the right vendor. Most companies usually have pre-approved vendor catalogs from which they can decide who to give the contract to. If not, you or your purchasing manager must first obtain and evaluate quotes from different vendors or suppliers to see who suits your needs the best.

3. Receipt of goods and raw materials into stock

This step concerns the delivery of the goods or materials in compliance with delivery terms and conditions. Once you’ve received the order your organization must then conduct an audit or quality evaluation to ensure that the vendor or supplier has adhered to all the terms and conditions previously agreed upon.

4. Invoice approval process

Post-order delivery the vendor will then send out an invoice for the payment required for that order. Your accounts or finance department must evaluate this invoice, verify the particulars and check for any errors or discrepancies. If there are errors the invoice must be sent back, if not it gets approved and is forwarded to the payments department.

5. Accounts Payable (AP) sends payment to suppliers

Lastly, we have the step that involves the actual payment of the cost of goods purchased. Once the invoice sent by the supplier is approved your accounts team can then move forward to complete the purchasing process by sending out the required payment to the particular vendor.

Again, as per the terms and conditions agreed upon this payment will be made one-time, recurring, or over a period of time.

What is procurement in business?

Procurement is a more specialized term used to describe the sourcing, negotiation, and selection of goods and services that are usually of greater importance to the company. Procurement in business is a more strategic approach to acquiring goods and services.

Procurement managers often have to obtain these goods and services with limited resources and reduced capabilities at their disposal. In doing this they have to follow a much more thought out and structured approach where a thorough process has to be followed to ensure company resources and requirements are both managed well.

8 step procurement process

Similar to purchasing, procurement systems also vary across companies and industries. However, these 8 steps sum up a general approach to an effective procurement strategy:

1. Know your requirements

Knowing what you want, how, when, where, and how much resources you have at your disposal to spend on the goods and services you want is integral to your procurement process. It helps set targets for you to reach and highlights limits you cannot cross.

2. Request a purchase

The individual or team that needs to make the purchase will then have to send a purchase request to the company. This part of the process is often done via e-procurement softwares. A procurement or financial controller will then evaluate the request made.

Once the request is sanctioned a purchase order will then be issued. If, however, it is rejected the employee will receive a letter or notification informing them of the same and the reasons behind the rejection.

3. Evaluate and choose vendors

Where you obtain your supplies will determine how good the quality of the materials or services obtained are. However, it will also depend on the resources you have at your disposal to make that particular purchase.

Most companies have pre-approved vendor catalogs or supplier lists filled with the details of entities they have already done or intend to do business with in the future. Procurement management must ensure that these lists are kept up to date and the vendors or suppliers are fully vetted.

They must also ensure that when choosing an entity from this list they keep resources and requirements in mind.

4. Negotiate the price and terms of the transaction

Negotiation is key to arriving at a contract where both parties wil have done good business. It is also a key part of the process because it gives procurement management a chance to alter any particular terms of the purchase agreement that might be outside of their requirements or budget.

To elaborate, this part of the procurement cycle entails analyzing aspects such as pricing structure, the scope of work, terms and conditions, delivery dates, and so on. More cost reduction potential, such as dynamic discounting, can also be obtained through detailed contract analysis and negotiation.

5. Create a purchase order

A purchase order is essentially a document containing the pricing, specs, and terms and conditions, as well as any other commitments of and for the goods and services to be purchased.

After having signed the contract you have to send this purchase order to your vendor. The vendor will then accept and acknowledge the order following which a legally binding contract will be formed.

6. Conduct 3-way matching

At this point of the procurement cycle procurement management will have to perform a three-way check to avoid any errors or discrepancies that might lead to significant revenue losses in the future.

They will have to check and verify the particulars of three essential documents - the purchase order, vendor invoice and packing slips. It is critical at this stage for your team to thoroughly vet these documents.

7. Complete the payment process and ensure requested goods/services are delivered

When sending the purchase order you must also ensure an invoice containing the prices of the desired products or services is also attached. After your company receives the deliverables, procurement management must match the purchase orders and invoice them to ensure quality and quantity.

Following this, procurement payment is to be released as per the terms agreed upon between the two parties. After receiving the goods you must also conduct an audit to ensure that the supplier has met the required quality standards.

8. Maintain records

To ensure bookkeeping and accounts are kept in order you must maintain records. For every step in your supply chain, make sure all documentation is saved for future audits. If not, you may have to face negative consequences.

How to improve your company’s procurement process

Procurement processes can be complicated for a number of reasons. They require a detailed approach wherein management needs to keep all moving parts in mind when engaging in negotiations or making arrangements. Some of the factors your procurement management team can keep in mind to improve this system could include the following:

1. Prioritize supplier relationships

Building healthy and long-lasting supplier relationships can go a long way in helping you streamline your procurement cycle. Strategic networking with the right vendors, building and maintaining relationships with them ensures fair, detailed and straightforward negotiations every time.

RFPs, for example, increase efficiency and help keep suppliers happy. Moreover, you may also get better deals as long as you stay in your suppliers’ good books.

2. Consolidate your supplier lists

Having a consolidated directory of trustworthy supplier lists at your disposal can save a lot of work for your teams. When you consolidate your suppliers in one place you have a ready list of go-to vendors who are guaranteed to meet your purchase requirements.

What this does is it removes the need for procurement management to have to conduct supplier research every time a purchase request comes up. This can save a lot of time and at the same time ensure that you have consistent suppliers who help you maintain quality uniformity.

3. Build a procurement policy

Having standard guidelines in place is beneficial to any process, including procurement. In fact, for both purchasing and procurement, the more established your policies and guidelines are the easier it will be for your teams.

Standardization is key here, it develops consistency and eradicates the need to develop customized approaches for every single purchase. Instead, a procurement policy that has clearly outlined steps will cut down on any extra work or time required.

4. Educate your employees

As the world continues to evolve, so do the nuances of finance. Training your employees, helping them upskill means that you will have a workforce that is best equipped to tackle challenges, especially new ones.

This principle is applicable to your procurement teams as well. The more knowledge your employees have, the more updated and educated they are on the workings of the industry, new developments and how to be efficient in general. This ensures that your procurement cycle is kept functioning at its smoothest.

5. Improve your purchasing systems

Your purchasing system, including Purchase Requests, Purchase Orders and invoice processing, must be streamlined. The easier it is for your teams to manage and operate this system the smoother your procurement cycle will be.

6. Invest in procurement automation

Arguably the most effective step you can take to improve your procurement process is to get your company procurement automation software. Digitizing your systems is one of the fastest ways to increase efficiency and be successful.

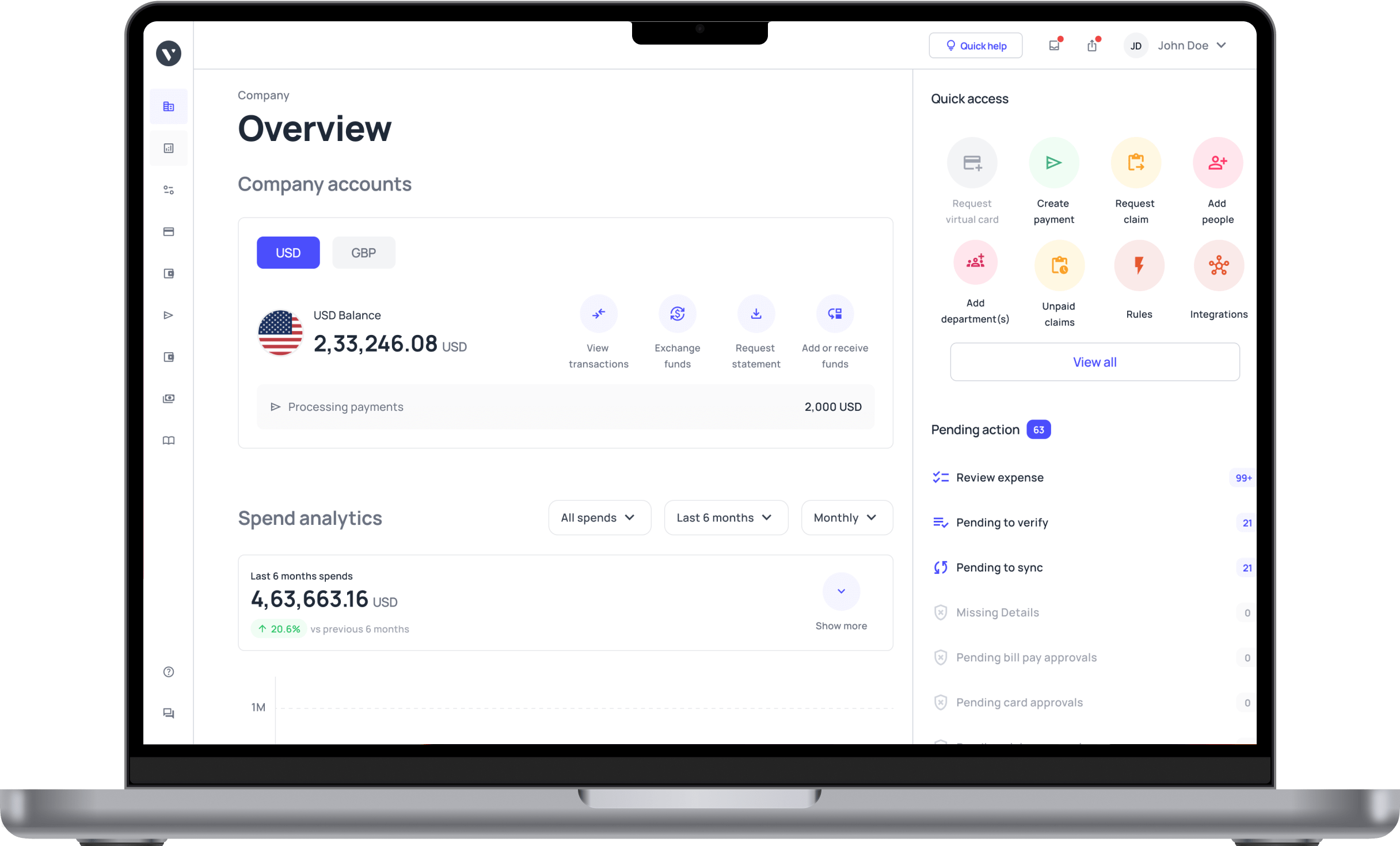

Most of the steps involved in procurement systems can be automated. There are expense management softwares, like Volopay, Brex, Ramp etc., that can easily automate steps like invoice processing.

Volopay's intake to procure software further enhances this automation by streamlining the entire procurement journey, from requisition to payment.

These services (SaaS) come well-equipped with AI that is capable of taking out most of the labour your team would have otherwise had to give. They also ensure the probability of human errors and discrepancies are either fully eradicated or kept at a minimum.

Key differences of purchasing and procurement

Purchasing and procurement might both be working in a similar context but are far from being one and the same. In fact, purchasing could be said to be a subset of procurement. Having a comprehensive understanding of the differences between the two is integral to having an effective system in place. Some of the main differences between the two are:

● Goals

The cost of your order is the focus of purchasing, while for procurement the value created and Total Cost of Ownership are the focus. The primary goal of purchasing is to minimize the cost of an order, procurement, on the other hand, has other objectives like risk mitigation, contract compliance, cost savings, ongoing supplier relationships, etc.

● Vendor relationship

Purchasing management usually tends to only work with the existing supplier base, and so, doesn’t focus much on building vendor relationships. On the other hand, procurement management considers building long-term, collaborative relationships with strategically sourced suppliers as one of its primary tasks.

Supplier Relationship Management (SRM) is a critical component in the procurement cycle. It positions suppliers as valuable strategic partners of an organization. This then further enhances the value of a vendor-organization relationship

● Pricing and value

Procurement in business is more concerned with the value that the goods or services acquired add to the organization, especially in the long run. Purchasing, on the other hand, is concerned with the cost or price tag that the desired materials come with.

● Proactive and reactive approach

The steps involved, reasoning and objective behind the two mean that procurement takes a proactive approach while purchasing is more reactive. Procurement processes are proactive in the sense that they entail a much greater degree of planning and strategizing before, during and after acquiring the materials required.

● Proactive and reactive approach

In the procurement vs purchasing debate another point of distinction is that purchasing processes are transactional while procurement processes are relational. Procurement aims to develop long-standing, win-win relationships with suppliers. Whereas, purchasing focuses on the efficiency of transactions rather than developing relationships.

● Order of operations

Procurement follows a much more elaborate order of operations than purchasing. It involves everything from identifying requirements to sourcing, contract closure as well as maintaining records. Purchasing is mostly a three-step process involving ordering, expediting and payment.

● Risk evaluation and mitigation

Since purchasing is purely transactional, it doesn’t accommodate identifying and mitigating risks. An organization may encounter multiple supply chain risks while engaging with vendors or suppliers. This could include operational risk, financial risk, data security risks, etc.

Procurement, on the other hand, maintains identifying risks as a primary function. It also moderates business impact and mitigates these risks by ensuring compliance guidelines are enforced amongst all the stakeholders.

Procurement and purchasing automation

Tracking payments, processing invoices, storing proofs of purchase, aggregating payment information, approval workflows - these are all examples of the tasks that your team should not have to be occupied with when there is automation.

Both purchasing and procurement are processes with multiple steps that would normally require plenty of paperwork and manual labour. However, with the help of Volopay's procure-to-pay software, you can cut processing times down from weeks to minutes.

When you automate purchasing and procurement processes using software like Volopay's procurement solution you’re also upgrading to a more efficient, well-oiled system. Automation means that the steps involved in your purchasing and procurement processes are much better protected against errors, discrepancies and fraudulent practices.

The software helps you track all steps in real-time and automatically keep a record of the same as well. Other perks and features like approval workflow, multi-currency wallets, corporate credit are added boosts that streamline both purchasing and procurement processes.

FAQs

Yes, procurement is a much broader process than purchasing since it involves more than just buying things. In fact, purchasing is often considered to be a subset of procurement.

Purchasing is not directly a part of accounting. However, all transactions your company makes, including purchases made, will have to be maintained in your books and therefore as a part of your accounting systems.

Procure-to-pay also known as the P2P is a process involving coordinated and integrated action taken to fulfill a requirement for goods or services at a reasonable price and in a timely manner. P2P follows a number of sequential steps as a part of its cycle. The steps range from need identification to invoice approval and vendor payment. These steps must be executed in a strict order.

To make changes, update or close a purchase order you need to complete a Purchase Order Amendment (POA). The POA is a duly authorized amendment issued in writing to the vendor or supplier by the purchaser, company or individual, to amend the Purchase Order.